POFI EDM TOOLING SYSTEM CO.,LTD

+86-0769 85071992

E-mail:info@pofi-workholding.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 10 Author: Site Editor Publish Time: 2025-03-15 Origin: Site

The Great Reveal of Mainstream Zero Point Positioning Systems

Currently, the mainstream zero-point positioning systems on the market include several system principles such as self-locking ball lock, the clamping pin with cylindrical screw, Eraling tube clamp locking method and so on.

This article mainly discusses the self-locking ball lockzero-point positioning system for the ball.

Representative brand: POFI, Erowa, System 3R

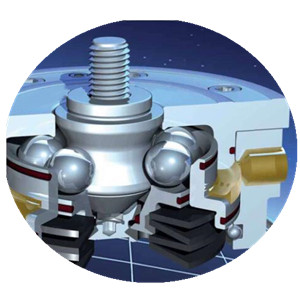

1.System Principles: The zero-point positioning system belongs to a normally locked mechanism, which opens when pressurised and locks when depressurised. When hydraulic or pneumatic pressure is applied to the zero-point positioning system, the pressure compresses the spring below the piston, causing the steel balls to spread outwards, allowing the male connector to be removed. When the power source is cut off, the spring pushes the piston upwards, which retracts the steel balls towards the centre, thereby clamping the steel balls.

2.System Features:

High Precision: The repeat positioning accuracy is less than 0.005mm, ensuring the consistency of the workpiece's position across different machines or processes.

High Efficiency: This system can significantly reduce machine downtime, improving production efficiency.

Modular: It allows for the modularisation and standardisation of fixtures, helping to save on fixture costs.

3. Standardised Interface: A unified standard interface has been established between different parts, machines, and workstations, promoting semi-flexibility in production.

4.Applicaion:

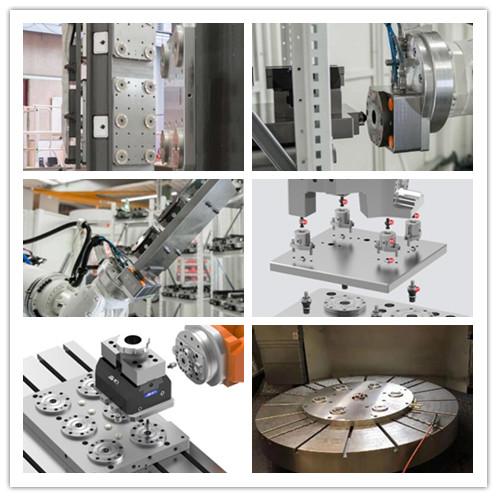

a. A multi-station vice is mounted on top of a vertical square box. The traditional method is to first align the square box, pre-position it using a central pin, level the square box's surface, and adjust its verticality. This operation requires a high level of skill from the workers and is very time-consuming, taking about thirty to forty minutes. However, with the zero-point positioning system, it only requires using lifting tools to suspend the fixture into the machine tool and position it correctly.

b.The end of the robotic arm uses a zero-point positioning system for the gripping and changing of fixtures, with each fixture equipped with a zero-point positioning joint, and the side joint is used for being grasped by the robotic arm.

c.The flexible automated production line is equipped with robots, a fixture library, and a zero-point positioning system. In the automated production line, processes such as chip blowing, airtightness testing, and clamping and releasing detection are of particular concern, especially since metal cutting requires convenient removal of metal shavings. The AMF zero-point positioning system features an automatic retractable dust cover and a turbo chip blower, which can completely eliminate the impact of dust and metal shavings on automation, while also providing clamping signal detection, releasing signal detection, and airtightness testing functions.